Products | Aluminum Anodizing System Equipment

|

|

| Anodizing system for architectural parts |

Automatic Anodizing system for electronic devices |

|

|

| Automatic Hard Anodizing Line | Horizontal Automatic Gantry Crane Anodizing Plant for architectural parts |

|

|

| Automatic Anodizing Line for Home Appliances |

Automatic Anodizing Line for Home Appliances |

|

|

| Anodizing Equipment for Window System |

Anodizing System |

Aluminum Anodizing Technology

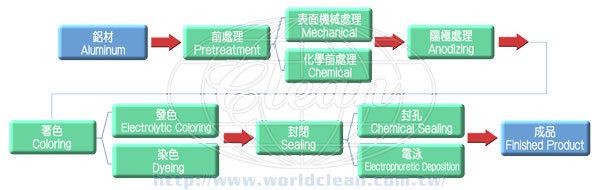

Anodizing (Anodic oxidation) is an electrochemical process in which an oxide (anodic) layer is chemically built on the surface of the metal. Now anodizing is a commonly used surface treatment, especially on Aluminum alloys after casting or extrusion for structural or architectural applications.

The anodizing process forms an oxide film, a hard, corrosion- and abrasion-resistant coating with excellent wear properties. This porous coating may also be colored using a number of methods, thereby enhancing its aesthetic value even as it protects the metal.

Anodized Aluminum is an important product for a number of industries, including aerospace and automotive manufacturers, as well as various sporting activities and most up-to-date electronic devices, like iPods, PDA, mobile phone, computer case, etc.

Many acidic solutions can be used for anodizing, but sulfuric acid solutions are the most common. Chromic, oxalic, and phosphoric acids are also used in certain applications.

By US military standard MIL-A-8625, it simply divides anodizing into three categories:

Type I - Chromic Acid Anodizing

Type II - Sulfuric Acid Anodizing

Type III - Hard Anodizing (Hardcoat)

Hard anodizing can get a very hard and thick oxide film. Electrolyte in low temperature and increase current density and voltage so oxide film is build as thick as 30-50μm or more and hardness up to around 500HV. Its durability, electrical insulation and corrosion resistance has been extensively applied in engineering industry.

|

|

| Chemical Polishing Plant |

Anodizing Unit for furniture parts |

|

|

| Vertical Automatic Anodizing Machinery | Central Control Room of Automatic Anodizing Plant |

Coloring

Electrolytic Coloring (2-step method): electrolytic coloring has widely applications in Aluminum alloys. After anodizing, Aluminum is immersed in an electrolytic bath containing metal salt. Metal salt deposits in the base of the pores while current is applied, showing colors in different shades through amount of deposition and refraction under light.

Dyeing: According to different requirement of Aluminum profile, colors may be added to oxide film. This process is dyeing treatment. After anodizing, the oxide film is formed and suitable for dyeing different colors.

There are two kinds of dyes:

- Inorganic metal salt dye

- Organic dye

Usage and purpose as below:

- Architecture extrusion profile: colors of brown, bronze, champagne, black, and golden.

- Decoration profile: chemical polished and colors of golden, carat golden, blue, red and etc by dyeing

Sealing

Seal oxide film composed by tiny beehive-like cells.

- Chemical Sealing: sealed in hot water over 90℃ or in chemical sealant.

- Electrophoretic Deposition: electrophoretic deposition coating (AED or CED paint)

Our Capability

Each different kind of anodizing system has its own setup, condition and processes. By searching on Internet, it's not hard to find the answers. However, when it comes to industrial production scale of 200 Tons/month or more, you may probably find a trusted and experienced anodizing equipment manufacturer and supplier with latest anodizing technology.

We offer a turnkey basis solution of anodizing plant including design, manufacture, installation, training and transfer of technical know-how of anodizing with periodic maintenance and after sale service as well.

Worldclean's anodizing system has following advantages:

Homogeneous surface structure

Homogeneous pore pattern

Reproducible results

Uniform coloring

Customized various types of anodizing line for Aluminum. Contact us to find out more.

|

|

|

|

|

|

|

|

Laboratory unit for small quantity production or lab testing purpose. Customizable size and design to meet your requirement. Contact us to find out more.

Laboratory unit for small quantity production or lab testing purpose. Customizable size and design to meet your requirement. Contact us to find out more.

- Turnkey Plant Equipmqnt

CE & ISO 9001:2008 Certification